The nuclear community tends to associate molten salts with the eponymous molten salt reactor. And well it should. MSR reactors use special liquids – molten salts – to operate at much higher temperatures than conventional reactors, auguring all sorts of advantages including efficiency, waste reduction and improved safety, among others.

It thus behoves the industry to develop and win regulatory approval for MSRs as future sources of CO2-free electricity and industrial heat.

But as 2013 gets under way (and as Mumbai’s Conference on Molten Salts in Nuclear Technology approaches), now seems like a good time to point out that the same thermal properties that make molten salts a potential nuclear tonic could also give them a broader role in the world’s energy mix.

Molten salts, as the name implies, are salts that melt when they hit a high temperature. Exactly how high depends on the particular salt (MSR reactors are expected to operate somewhere around 700 or 800 degrees C). They are stable, they don’t boil easily (a good thing when you need them in liquid form) and they flow like water.

It’s well known that molten salts could one day soon help store heat at solar farms, where they would circulate and absorb the sun’s heat by day and hold onto or release it at night or some later time when the sun doesn’t shine. In that scenario, molten salts would help overcome one of solar electricity’s shortcomings – its inability to generate electricity around the clock.

OIL PLUS SALT EQUALS HYDROGEN

But here’s another potential use I stumbled across recently that could hold just as much promise, and probably more, than the solar application: Molten salts can help extract hydrogen while at the same time removing CO2 from hydrocarbons like oil sands, according to Western Hydrogen Ltd., a Calgary-based company.

Deploying molten salt technology developed at the U.S. Department of Energy’s Idaho National Laboratory, Western Hydrogen thinks it can pull hydrogen out of “carbonaceous” materials such as the bitumen in the oil sands common in Canada, as well as from other petroleum residue and petroleum coke.

The so-called molten salt catalyzed gasification process runs water and carbon compounds through a bed of high temperature (around 850 degrees C) molten salts, out of which comes hydrogen and “sequestration ready” carbon dioxide, Western Hydrogen’s website explains in a “low carbon” energy scenario.

The hydrogen could be used as transportation fuel in the elusive hydrogen economy, and it could also feed petrochemical production processes which today use hydrogen derived from more expensive and less environmentally friendly processes, Western Hydrogen claims.

Western Hydrogen also plans to use its process to yield carbon monoxide and deuterium (an isotope of hydrogen that, incidentally, is key to nuclear fusion plans) that it would combine into synthetic liquid fuels.

CANADIAN KICK-OFF

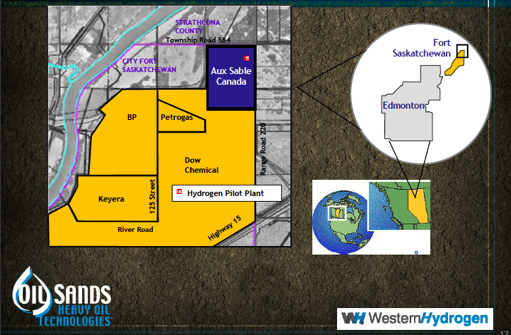

The company hopes to start operating a pilot plant during the first half of this year near Fort Saskatchewan, Alberta in partnership with Aux Sable, a Canadian company that processes “offgases” from oil sands and would thus provide Western Hydrogen with a feedstock of presumably bitumen. The plant is being fabricated by Burlington, Ontario-based Zeton.

Western Hydrogen, which says it funded the DOE project and has exclusive rights to the technology, hopes to establish a larger demonstration plant by late 2014 and to be “commercially ready” by 2015. It appears to be targeting the oil sands industry as a main source of raw material. Chairman Guy Turcotte and CEO Neil Camarta have extensive experience in the oil and oil sands industry.

The company also envisions a “zero carbon” hydrogen production process in which it would feed algae and water into the molten salt bed and route the resulting CO2 back into an algae farm to help replenish the hydrogen production process. According to the company’s website, the process could also tap other biomass sources such as wood chips.

Western Hydrogen’s fondness for molten salts extends to other processes as well. In partnership with Salt Lake City based Ceramatec, it is developing a molten salt technique to “upgrade” bitumen into a pipeline-ready heavy fuel oil.

As I’ve pointed out here before, it seems that the money and the will to develop and use alternative reactors that promise a CO2-free energy future could ironically come in large measure from the fossil fuel industry, which could use the new technologies to improve and clean up their own production of CO2-emitting fuels (China certainly has such plans).

It seems the same impetus will be a driving force for molten salt technologies of various sorts.