When it comes to fission reactor designs, there’s nothing quite as safe, efficient, meltdown-proof, waste-light and proliferation-resistant as a molten salt reactor (MSR), many nuclear experts believe.But as the community of MSR developers perfects its designs, it will have to overcome a number of engineering and materials challenges. One of those, according to a leading expert: Obtaining the elements to make the elixirs – the molten salts – that define the reactor.First, a quick review.

As it says on the label, a molten salt reactor (MSR) uses a liquid salt as the fluid that both carries the fuel (uranium, thorium or even a mix of plutonium among other possibilities) and serves as the coolant that picks up heat from a reaction and transfers it to a turbine.It is the liquid nature that underlies all the reactor’s advantages, not the least of which is safety. As guest blogger John Laurie pointed out here recently , liquid reactors – MSRs – cannot encounter a meltdown accident because they are already “pre-melted”. If things overheat, MSR designs allow the liquid fuel to drain harmlessly away into a holding tank.

A good MSR salt can continue to flow as a liquid at temperatures far above the operating temperature of conventional solid-fuelled, water-cooled reactors. MSR developers envision temperatures in the 700 degree C and 800 degree C range, a level that improves generating efficiencies and that makes the MSR highly useful as an industrial heat source.

WORTH ITS SALT

Not all salts are up to the task, however. The one that many MSR developers believe best suited for the job is called lithium fluoride beryllium fluoride, or FLiBe. (It’s so much associated with MSRs that it’s the namesake of one well known MSR company, Huntsville, Ala.-based Flibe Energy).But there’s potentially one big problem with FLiBe:

Obtaining the lithium isotope called lithium-7 that FLiBe requires.Lithium-7 occurs in natural lithium, where it is the main isotope, cohabitating with a little bit of another isotope, lithium-6. Common lithium is 92.5 percent “7” and 7.5 percent “6.”The two isotopes together form regular lithium found in everyday items like cellphone and computer batteries. But separating them is not straightforward.

According to chemist Dr. Stephen Boyd, chief technology officer of Aufbau Laboratories, Blue Point, N.Y., only two countries do it – China and Russia – and they use a separation process that relies on mercury, a hazardous substance that requires great care. Mercury is infamous in history for causing neurological disorders among 19th-century hat makers – giving rise to the term “mad hatter disease.”

The U.S. government abandoned the mercury method a number of years ago at its former lithium separation facilities at Oak Ridge National Laboratory in Tennessee. It recently announced a $120 million mercury clean up program there. Some reports have suggested that the inexplicable loss of a large amount of mercury from Oak Ridge also played a role in the decision to halt mercury-based lithium separation.

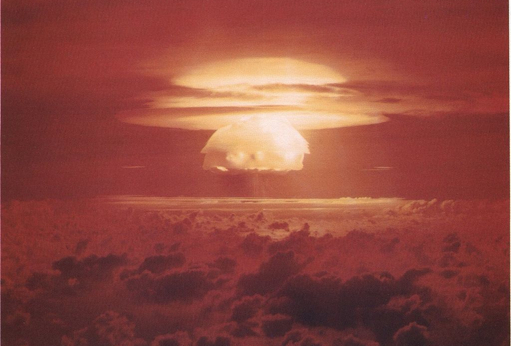

Another use for lithium. The U.S. used lithium-6 and hydrogen to fuel this thermonuclear detonation on Bikini Atoll in the Pacific Ocean on March 1, 1954. The Department of Energy’s defense-linked Y-12 group monitors lithium production.

So why was the U.S government extracting lithium-7 in the first place? Because it uses lithium-7 as a neutralizing agent – a pH balancer – in the small reactors that power the Navy’s fleet of nuclear submarines and aircraft carriers (commercial nuclear operators use it in the same way). Lithium-6 cannot be used in this process because it would transmute into potentially dangerous tritium (more on that in a moment).

The U.S. lithium separation process has been closely controlled by the federal government over the years, and not just because it wants to assure a supply of lithium-7 for its naval vessels.Another reason: The enrichment of lithium into lithium-7 by definition also yields lithium-6, a substance with nuclear weapons links. Lithium-6 can be used to make tritium, a hydrogen isotope that is a fuel in hydrogen bombs (which work on the principles of fusion power, releasing energy by fusing tritium with another hydrogen isotope, deuterium).

OAK RIDGE IS WATCHING

With such deadly and national security implications, the government controls lithium-7 and lithium-6 enrichment through its Y-12 program, an Oak Ridge-based operation that resides in the Department of Energy but which serves national security and defense purposes. As the DOE group’s website notes:

“Y-12 helps ensure a safe and effective U.S. nuclear weapons deterrent. We also retrieve and store nuclear materials, fuel the nation’s naval reactors, and perform complementary work for other government and private-sector entities.”

What this all suggests is that there’s an opening for a new lithium-7 extraction process. However, any company attempting such a development will have to work under the watchful eye of DOE’s Y-12 group.

That’s what Dr. Boyd has in mind at Aufbau. Boyd, who wrote a guest blog here earlier this month in which he cautioned about other materials challenges facing MSRs, says he is developing a non-mercury process. He declines for now to reveal details of his technology, but says he has been in contact with Y-12.The knock-on effect for anyone in the MSR business is that they might find supplies of lithium-7 to be tight, at least until new potential supplies such as Aufbau’s or others come around.

REACHING FOR ANOTHER

That might be one reason why several MSR developers about whom I’ve written recently are considering salts other than the lithium-7 reliant FLiBe. A number of salts have the similar “eutectic” properties of FLiBe that minimize the chance of them solidifying (just like you don’t want your salt to boil, you also don’t want it to turn into a solid).Canada’s Terrestrial Energy, for instance, is considering using sodium-based salts.

Thorium Tech Solution is contemplating FLiNak, which is a combination of sodium, potassium and lithium. (There are reasons other than the lithium component for choosing a different molten salt. TTS has expressed concerns with FLiBe’s beryllium, an element that might disagree with the plutonium that will form part of TTS’s liquid fuel).Each of these has its trade-offs. They can be less expensive and easier to obtain, but some of them can damage MSR plumbing.Boyd believes it makes the most sense to stick with FLiBe for commercial, scientific and national-security reasons.“FLiBe is a very good eutectic for MSRs,” he notes. “It’s one of the best, but you can run into the lithium problem right away.”

He also notes that there’s a business case for sticking with lithium-based FLiBe, because there are valuable markets outside of nuclear reactors for lithium isotopes and related products. He claims that lithium-6 sells for $1 million per kilogram.Stay tuned for more on Boyd’s lithium enrichment ideas. I met with him and with other MSR and materials mavens at the Thorium Energy Alliance Conference in Chicago last week, a gathering that was full of bright ideas on the development of alternative and safe nuclear power. Among them: How one U.S. politician thinks thorium reactors developers can find funding. Watch for my reports.