Do you know where the chain reaction occurs in a nuclear power plant? It happens in the reactor core, where fuel rods containing nuclear fuel are placed. Control rods regulate the reaction by absorbing neutrons, while a moderator slows down the fast-moving neutrons. The coolant system helps maintain the core’s temperature. Understanding this crucial part of the nuclear power plant is essential for comprehending how it generates electricity.

Reactor Core

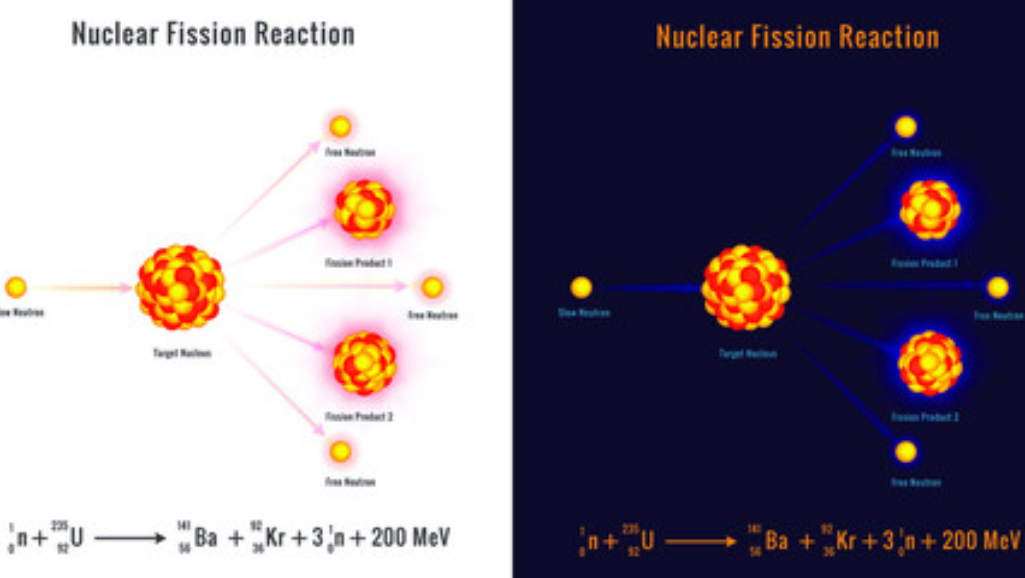

In the reactor core, the chain reaction occurs when you introduce fuel rods into the highly controlled environment. The reactor core is the heart of a nuclear power plant, where the nuclear fission process takes place. This process involves the splitting of atomic nuclei, releasing a tremendous amount of energy. The fuel rods, typically made of uranium-235 or plutonium-239, contain the necessary fuel for the chain reaction to occur.

When the fuel rods are inserted into the reactor core, the neutrons released from the fission of one nucleus collide with other nuclei, causing them to split as well. This creates a chain reaction, where each fission event releases more neutrons, leading to a continuous and self-sustaining process.

To ensure the stability and control of the chain reaction, the reactor core is designed to have a specific neutron flux distribution. Neutron flux refers to the density and distribution of neutrons within the core. It is carefully controlled to maintain a critical state, where the rate of neutron production equals the rate of neutron loss. This critical state allows for a steady and controlled release of energy.

Fuel Rods

To continue the discussion from the previous subtopic, the fuel rods play a crucial role in initiating and sustaining the chain reaction in a nuclear power plant. Fuel rods are an integral component of the reactor core, where the nuclear fission process occurs. These rods contain fuel pellets, usually made of enriched uranium or plutonium, which undergo controlled nuclear reactions.

The nuclear fission process involves the splitting of atomic nuclei, releasing a tremendous amount of energy. Fuel rods are designed to house the fuel pellets and control the fission process. The pellets are arranged in a specific pattern within the rods to optimize the chain reaction. As the fuel undergoes fission, it releases heat, which is then used to generate steam and ultimately produce electricity.

Safety measures are of utmost importance in handling fuel rods. The rods are encapsulated in a cladding made of a corrosion-resistant material, such as zirconium alloy, to prevent the release of radioactive material. Additionally, the reactor core is surrounded by multiple layers of containment structures to ensure the confinement of radiation. Strict protocols and regulations govern the handling, storage, and disposal of fuel rods to minimize the risks associated with nuclear energy.

Control Rods

Control rods play a crucial role in regulating the chain reaction within the nuclear power plant by absorbing neutrons. These rods are made of materials such as boron or cadmium, which have a high neutron absorption capability. By inserting or withdrawing control rods into the reactor core, the operators can control the rate of the nuclear reaction.

The control rod operation is based on the principle of neutron absorption. Neutrons are emitted during the fission process, and if left unchecked, they can continue the chain reaction and lead to an uncontrolled release of energy. The control rods are designed to absorb these excess neutrons, thereby reducing the neutron population and slowing down the reaction rate. This allows the reactor to operate safely and efficiently.

When the control rods are fully inserted into the reactor, they absorb a significant number of neutrons, effectively shutting down the chain reaction. Conversely, by withdrawing the control rods, fewer neutrons are absorbed, allowing the chain reaction to proceed at a desired rate. The position of the control rods is carefully monitored and adjusted by the operators to maintain a stable and controlled nuclear reaction.

Moderator

The next component essential for the chain reaction in a nuclear power plant is the moderator, which works in conjunction with the control rods to regulate the rate of the reaction. The moderator plays a crucial role in a nuclear reactor by slowing down the fast-moving neutrons produced during nuclear fission. When uranium-235 or plutonium-239 atoms undergo fission, they release a large amount of energy in the form of heat and produce high-energy neutrons. These neutrons need to be slowed down in order to efficiently cause further fission reactions.

The moderator is typically made of materials with high atomic masses, such as water, graphite, or heavy water. These materials effectively slow down the neutrons through collisions, reducing their kinetic energy. By slowing down the neutrons, the moderator increases their likelihood of being captured by other fissile atoms, such as uranium-235 or plutonium-239. This results in a sustained chain reaction.

The choice of moderator depends on several factors, including the type of nuclear reactor and the desired characteristics of the chain reaction. Water is commonly used as a moderator in pressurized water reactors (PWRs), while graphite or heavy water may be used in other types of reactors. The moderator, along with the control rods, ensures that the chain reaction remains controlled and stable within the nuclear power plant.

Coolant System

Now let’s talk about the coolant system, which is an essential component in the nuclear power plant and is responsible for transferring heat away from the reactor core. The coolant system plays a crucial role in maintaining safe operating temperatures within the reactor. It consists of pumps, pipes, and a coolant fluid that circulates through the reactor core, absorbing and carrying away the excess heat generated during the nuclear chain reaction.

The primary function of the coolant system is to ensure effective heat transfer, preventing overheating of the reactor core and potential damage to the fuel rods. The coolant fluid, usually water or a mixture of water and chemicals, is pressurized by pumps to flow through the reactor core at high velocity. This high-speed flow allows for efficient heat absorption from the fuel rods.

In the event of a pump failure, the coolant system can face significant challenges. Without the proper circulation of the coolant fluid, the heat transfer process is compromised, leading to a rapid increase in temperature within the reactor core. This can potentially result in a loss of control over the chain reaction and pose a severe threat to the safety of the nuclear power plant.

Therefore, regular maintenance and monitoring of the coolant system, including pump performance, is crucial to ensure its reliable operation. Effective heat transfer is essential for maintaining the stability and integrity of the nuclear power plant, and any issues with the coolant system must be addressed promptly to prevent accidents and ensure the safe generation of nuclear power.