The more I watch developments in the molten salt reactor field, the more impressed I am by the variety of innovative approaches.While every molten salt reactor project I’ve encountered traces its inspiration and probably its basic design to the 1960s Oak Ridge National Laboratory project in Tennessee, the number of modifications that different labs are pursuing is starting to resemble the type of competitive differentiation that defines a free market.

Before I get too carried away, let me acknowledge that MSRs are a long way from the market (although with the right breaks, not as long as some would believe). Thus, it’s admittedly premature to compare them to the thriving technological leapfrogging of, say, the automobile or information technology industries.

But MSR companies nevertheless are in the early stages of trying to one-up each other as they all chase the general goal of building a reactor that runs on liquid fuel rather than on conventional solid fuel, and that provides a host of improvements in safety, efficiency and long-lived waste reduction.

The most recent case in point comes from the newest of the statups: Terrestrial Energy Inc., based in Ottawa Canada, and run by co-founder, president and chief technology officer David LeBlanc.Dr. LeBlanc is an MSR expert who in January wrote a guest blog here in which he pointed out among other things that it would be in the best interest of the MSR industry to keep designs as simple as possible in order to stand a chance of commercializing within a reasonable time frame.

That advice struck me as sensible, so I made a point of following up with LeBlanc, who incorporated Terrestrial in late 2012 after several years of running an MSR intellectual property company called Ottawa Valley Research Associates.We spoke by Skype last week, when LeBlanc explained the pragmatic reasoning behind his simplicity push, noting that, “You cannot underestimate the cost of nuclear R&D.;”

BURN DON’T BREED

He outlined his plan for simplicity. In keeping with the theme, let me attempt to keep it simple: Terrestrial Energy is departing from the original Oak Ridge scheme that called for a two-fluid molten salt reactor that would breed its own fuel. Instead, Terrestrial’s design calls for a single fluid reactor that would “burn” rather than breed. In the nuclear lexicon, LeBlanc’s reactor is known as a “burner” or a “converter”, not a “breeder.”While a two-fluid breeder would be the “Ferrari” of MSRs, the world cannot afford to wait for its development, given the desperate need for CO2-free energy sources such as MSRs, notes LeBlanc.

Dual fluid breeder MSRs face a number of extra challenges that will prolong their development beyond that of a single fluid MSR. Among them:

- The infamous “plumbing problem” that vexed Oak Ridge. In a two-fluid design, one fluid continuously breeds fuel, feeding it into another fluid where the nuclear reaction takes place. The pipes and materials that house and separate the fluids are subject to damaging wear and tear.

- Dual fluid breeders require constant removal of fission products, which are the short-lived radioactive waste products of a nuclear reaction (different from the long-lived “actinide” wastes like plutonium) “That requires a lot of R&D; and a lot of capital to develop,” notes LeBlanc, who points out that in the 1960s, Oak Ridge had planned to remove fission products on a 10-day cycle by removing a tenth of the salt each day.

Ergo, LeBlanc’s single fluid approach, which uses denatured uranium – low enriched uranium that is useless for weapons fabrication.Compared to a breeder MSR, a burner based on denatured uranium has the obvious disadvantage of not running forever on its bred fuel. LeBlanc downplays that, noting a once-through cycle can last for up to 30 years in a single fluid MSR. In addition, the actinides – which are much less than in conventional reactor waste – could potentially be removed at that point and recycled into the next fuel batch, minimizing long-term waste storage needs.

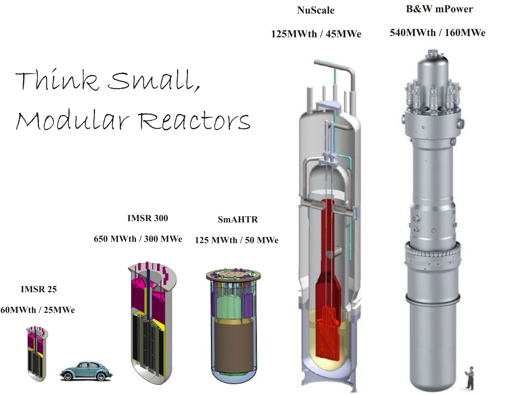

Packing a punch. LeBlanc’s high power density design means that his IMSR can be smaller than other modular reactors. Above, he compares a 25 MWe and 300 MWe version of the IMSR to the SmAHTR design, and to more conventional modular reactors from Nuscale and Babcock & Wilcox. He borrows from a famous VW ad slogan. Spot the Beetle – it’s to scale.

Those 30 years, though, would require annual top-ups of uranium. But as LeBlanc points out, the amount would be only about one sixth of the uranium requirements for today’s conventional solid fuel reactors.Toward the end of its molten salt reactor days, Oak Ridge designed and built a single fluid MSR to run on denatured uranium, along with thorium, called a DMSR.

GET SMAHT

Terrestrial Energy is drawing on that design, but is combining it with principles borrowed from another technology called SmAHTR, for Small Modular Advanced High Temperature Reactor.The 50-megawatt (electric) SmAHTR is a conceptual innovation at Oak Ridge. It is a small version of the liquid cooled 1500 MWe AHTR – on which Oak Ridge is collaborating with China – that places the heat exchange inside the reactor vessel.SmAHTR and AHTR introduce liquid cooling (molten salts) to high temperature next generation solid fuel reactors such as those that use TRISO fuel – pebble bed reactors – and those that use prismatic blocks where the fuel is embedded in graphite blocks that serve as the moderator.

Those reactor designs have in the past typically used helium gas as a coolant, which presents various mechanical difficulties and requires high pressure.LeBlanc believes that by switching the fuel into the molten salt, it offers many benefits of liquid fuel while retaining innovative features of the SmAHTR design. One such benefit: The reactor generates heat directly in the liquid fuel, which permits higher power density operation.

Placing the heat exchanger inside the reactor vessel rather than outside – as with some other MSRs – helps.That, in turn, will allow Terrestrial to build smaller but equally powerful reactors compared to other small modular manufacturers that are using more conventional solid fuel, water-cooled designs, such as Babcock & Wilcox (see diagram above).

NAME THAT REACTOR

Not to be outdone on the nomenclature front, and in keeping with the MSR industry’s nascent differentiation trend, Terrestrial gives its reactor a unique name: the Integral Molten Salt Reactor, or IMSR.The IMSR will also include patent pending innovations, on which LeBlanc declines to publicly elaborate.Another IMSR feature: It will use a core of graphite moderator slabs between which the fuel flows which LeBlanc says, “allows other advantages like tricks to limit the amount of neutrons reaching the vessel wall.”

This addresses a problem that developers of liquid fuel fast reactors will find difficult to crack, he notes.With the right combination of power density and core design Terrestrial could build the IMSR with upwards of six times the electrical output of the same size vessel as SmAHTR. It would require replacing the graphite core every four years. The fuel would reside temporarily in a holding tank during the core swap. That marks an improvement over the SmAHTR concept, which requires a swap of the solid fuel core every four years.LeBlanc envisions IMSR reactor sizes ranging from 25 MWe to 300 MWe.

As with other MSR startups, such as the Japanese single fluid company Thorium Tech Solution, LeBlanc is undecided on exactly what salt he’ll use. While FLiBe salt (lithium fluoride and beryllium fluoride) is commonly associated with dual fluid MSRs, its lithium isotope is problematic, for reasons I’ll examine in a subsequent blog.LeBlanc says he is considering alternatives including sodium based salts.

In the long run, he has not ruled out a breeder design or thorium fuel, but for now, he’s focused on the single fluid uranium reactor.“The burner is less challenging than the breeder,” notes LeBlanc. “It greatly reduces technological and regulatory hurdles.”His goal is to commercialize the Terrestrial reactor by 2021. With his simple and SmAHTR combination, he stands a reasonable chance.